We proudly uphold our family’s legacy as a trusted name in the spice industry Since 1940—a name synonymouswith quality and expertise in chilies and spices. Based in Byadgi, Asia’s second-largest market for dry red chilies, We lead SAN with a steadfast commitment to delivering unparalleled freshness, with a relentless focus on quality, and sustainability in chilies and spices. Our journey began decades ago, and over the years, we’ve established ourselves as the recognized leader and top purchaser in the Byadgi chili market. At SAN, we prioritize sourcing the finest chilies and spices, ensuring every product upholds the highest standards. Our passion lies in preserving our rich heritage while innovating for the future, and expanding SAN’s footprint in global spice markets.

With deep roots in the industry and a passion for innovation, We strive to bridge tradition with modern practices, sharing the rich flavors of chilies and spices to homes and businesses worldwide. At SAN, we value transparency, sustainability, and excellence in every aspect, continuing to set benchmarks in the spice industry.

Cold Storage

Sun Drying Yards (10 Lakh Sqft)

Sustainability and Framer Support

State of the art facility

To be a globally recognized leader in premium chilies and spices, delivering excellencethrough heritage, innovation, and sustainability.

We deliver premium chilies and spices, uphold sustainability, and innovate while preserving authenticity and trust.

We uphold quality, heritage, sustainability, and customer focus through authenticity, innovation, and responsible practices.

SAN’s sourcing operations extend beyond Byadgi, with a vast procurement network spanning Karnataka, Andhra Pradesh, Madhya Pradesh, Gujarat, Rajasthan, Assam, and other regions. The company works closely with farmers and sources products directly from Agricultural Produce Market Committees (APMCs) in these regions. By leveraging both direct farmer relationships and established market systems, SAN ensures a reliable, year-round supply of premium-quality chilies.

An essential aspect of SAN’s procurement strategy is its focus on sustainable and regulated farming practices. The company has built a dedicated farmer network specializing in IPM (Integrated Pest Management) chilies. These chilies are cultivated using environmentally friendly farming techniques that minimize pesticide use. This approach ensures compliance with European Union (EU) and United States (US) food safety regulations, enabling SAN to serve the stringent requirements of international markets.

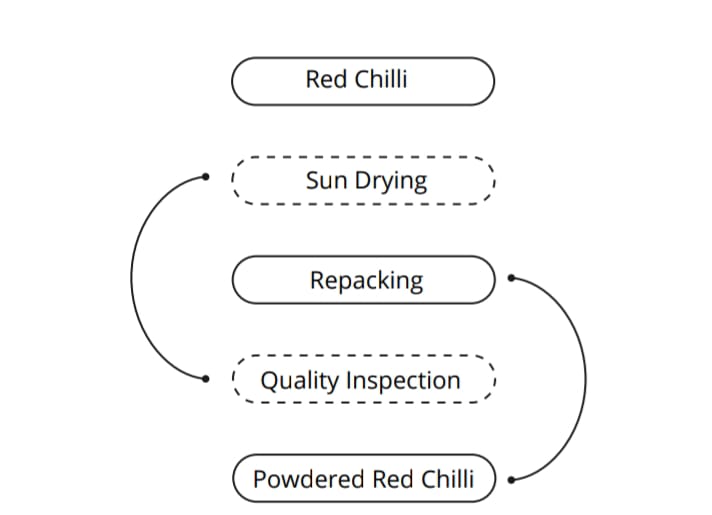

After procurement, the chilies are transported to SAN’s advanced processing facilities, which include two grinding units with a combined capacity of 20 MT per day. These units use state-of-the-art machinery to process the chilies into fine, consistent powder while retaining their natural flavor, color, and aroma.

For whole chilies, the raw material undergoes cleaning, sun-drying, and sorting to ensure only the finest products are packed. Each batch is subjected to rigorous quality checks, including tests for moisture content, pungency, capsaicin levels, and compliance with international safety standards.

Quality control is a cornerstone of SAN’s operations. Every batch is tested for factors such as moisture content, pungency, capsaicin levels, and compliance with international safety standards. By maintaining such stringent quality checks, SAN ensures that its products meet the highest standards of flavor, color, and safety.

An essential aspect of SAN’s procurement strategy is its focus on sustainable and regulated farming practices. The company has built a dedicated farmer network specializing in IPM (Integrated Pest Management) chilies. These chilies are cultivated using environmentally friendly farming techniques that minimize pesticide use. This approach ensures compliance with European Union (EU) and United States (US) food safety regulations, enabling SAN to serve the stringent requirements of international markets.

SAN employs modern packaging techniques designed to preserve the quality and integrity of its products. Bulk packaging options cater to wholesalers and food manufacturers, while smaller consumer-friendly packages are ideal for retail distribution. The company’s well-established logistics network allows it to serve both domestic and international markets with efficiency and reliability.

Under its consumer brand Sanwe Foods, SAN offers a variety of spices and masalas. Sanwe Foods includes a curated range of spice blends, seasonings, and single-origin spices, designed to deliver authentic flavors to households and professional kitchens alike. The brand is gaining recognition for its quality and consistency, expanding SAN’s reach in the retail market both in India and abroad.

SAN is deeply committed to sustainability and the welfare of its farmer network. By fostering long-term relationships with farmers and offering technical guidance, the company helps improve agricultural efficiency and crop yields. SAN also promotes sustainable farming practices through its IPM chili initiative, ensuring environmental responsibility while meeting the growing demand for pesticide-free products in global markets.

This dedication to sustainability has earned SAN recognition as a trusted partner in international markets, with key achievements including supplying 18,000 tons annually and generating 270 crores in annual turnover. SAN’s integrated farm-to-finish approach ensures that only the highest quality spices reach customers worldwide.

As manufacturers, we take pride in overseeing the entire production process— from sourcing fresh chilies from trusted farms to processing, grinding, and packaging them at our advanced facility. Our 20 MT/day grinding unit is equipped with the latest technology to ensure hygienic, efficient, and consistent output for retail, industrial, and bulk buyers.

After procurement, the chilies are transported to SAN’s advanced processing facilities, which include two grinding units with a combined capacity of 20 MT per day. These units use state-of-the-art machinery to process the chilies into fine, consistent powder while retaining their natural flavor, color, and aroma At the facility, pre-crushing lines are installed for the preparation of various cut sizes of chillies, Before crushing, the product is cleaned through different stages. Zig-zag classifiers are used for removing heavy admixtures and stones, which operate according to density difference, and the material is conveyed for further processing.

By regulating air pressure during aspiration of the product, light admixtures and fibers can be removed. Our machine can also be used to remove farm level contaminants that may accompany farm products. The online installation of magnets removes ferrous impurities as well as sifters with varying screen sizes so that the final product fits the required cut size and removes fine powders for better aesthetic appeal.

SAN’s integrated farm-to-finish approach ensures that only the highest quality spices reach customers worldwide. From sourcing chilies directly from farmers and markets across India to processing, storing, and distributing premium products, SAN’s operations exemplify efficiency, quality, and sustainability. By leveraging its extensive farmer network, cutting-edge facilities, and commitment to international standards, SAN remains a leading player in the global spice market. Through its consumer brand Sanwe Foods, the company continues to expand its presence in the spice industry, offering flavorful and authentic products that meet the needs of both individual consumers and businesses worldwide.